Page 1

LILAC Scanning

ECB Scanning Manufacturing Flow

Channel Weld, Assembly Weld, Finishing, Order Control.

Page 2.....

Page 3.....

Page 4.....

Page 5.....

Page 6.....

Table of Contents

1. Manufacture and Scan RAW Stock into Warehouse

- Produce a Raw bar and place it to Inventory. That is, there is no Sales Order for this Product.

2. Sell Finished Product from RAW Stock Warehouse

- Use a raw product to fulfill a Sales Order. This is a core activity, the customer can determine the type of finish the bar gets. That is, the bar is there waiting for the order to come through, to determine the finish. That is, the bar does not have to be made from scratch, thus reducing delivery time.

3. Manufacture and Scan FINISHED Stock into Warehouse

- Produce a finished bar from scratch for Inventory. That is, there is no current Sales order for this product. Does it get wrapped always to protect the finish? Not boxed? Should/does this product need to go over Order Control to be wrapped?

4. Sell Finished Product from FINISHED (boxed or un-boxed) from Stock Warehouse

- A Sales Order picks up a finished product, despatches and invoices it. Where this bar comes from will depend if it is wrapped, boxed, or sitting finished in the warehouse. Is it wrapped to protect the finish and keep dust off?

5. Sell Finished Product from Sales Order

- A Sales Order, from the Web or otherwise, manufactures a finished product from scratch, finishes and despatches it.

Possible inclusions -

Channel Weld

Mounts

Bending

etc

Basic Overview LILAC Desktop and Web Orders

- A bar may start with a: Web Sales Order, LILAC Keyed Sales Order, LILAC Keyed Production Order, in any case, each of which must have a process associated (ie Polished, Stock, Raw, etc) to progress to a Work Order.

- Where there is more then one different product on a Sales or Production Order, each (different, not items) product will be given it's own Work Order. That is a Work Order will only have one product Code on it, there may of course be more that one manufactured, ie, 6 x ABCXYZ.

- The scanning process then takes to Work Order all the way through the factory.

- Finially the invoice scan at Despatch progresses the Work Order into an Invoice, triggering automatic emailing, that is to say that this process is not performed on a LILAC Desktop.

Basic Overview of Manufacturing Flow

....... > Channel Weld > Assembly Weld (New Weld Job > Weld Complete) > New Finish Batch > Finish Return > Order Control > Wrapping Scan > Despatch

Warehouses

New Finisher Batch -> Goes to a location defined at Documents > Warehouse > Location.

Warehouse ID = F Finishing

Locations at this warehouse include internal and external finishing locations.

Returned Finished Bar -> Goes to a location defined at Documents > Warehouse > Location.

Warehouse ID = 0 F10 Warehouse.

Locations at this warehouse are 48 pages of physical locations.

Relevant Reports

Reports > Production > .................

Reports > Scanning > .................

Page 2

ECB Scanning Manufacturing Flow

1. Manufacture and Scan RAW Stock into Warehouse

Produce a Raw bar and place it to Inventory. That is, there is no Sales Order for this Product.

LILAC Desktop

A. Production Order. Process: Raw Stock. (Don't do Stock Raw, this is to sell a raw bar which is rare).

> Work Order.

B. Work Order.

> *Labels: Tag with Hole - Print.

- Once the bar is Work Ordered it will appear at: Documents > East Coast Bull Bars > Welding Jobs - Ribbon Button 'Refresh' may be needed.

- Work Orders are listed by ship date, not Work Order number.

- It needs to be released here, (Release All affect one page at a time).

- The Work Order can be asigned to an employee to designate it for the welder, otherwise (does?) the welder may get the next available released Work Order.... that does not have a Employee asigned to it.

- Following Welding Complete, the Work Order will drop off Documents > East Coast Bull Bars > Welding Jobs... with a refresh, which is a programmed task on the live big screen at ECB.

MC3300 Scanner Running LILAC Despatch Manager

1.0 Sign In

- Response "Type Company Id / Scan User" -> Done (Scan LILAC User Barcode.....z001).

- Response "Root Menu".

2.0 New Weld Job - Gives Welder a Work Order.

- Response "Scan Employee Badge"-> Done (Scan Employee Badge).

- Response (If no job) "No Job for EMP??" Go to: Documents > ECB > Welding Jobs: Refresh. This will release a job.

- Response. Gets assigned an available Work Order. "Welder RE??? ? on job WO??? Product Code x Quantity".

END OF CYCLE ICON (should appear?).

- At this stage he doesn't / he is not asked to scan the Raw Stock Barcode he is working on. He only does this when he finishes...which is a bit strange.....as he could well be working on the wrong bar....only to find an incompatable scan at the next step Welding Complete.

Response could request Scan Raw Stock Label: From Raw Stock Work Order.

- Next step go back in menu to find Welding Complete.

2.1 Welding Complete

- Response "Scan Employee Badge"-> Done (Scan Employee Badge)

- Response "EMP?? Active Location 3z 999 Scan Labels"-> Done (Scan Raw Stock Label: From Raw Stock Work Order)

- Response "WO??? ? to location 3z 999 Order Control:

- Work Order Complete END OF CYCLE ICON (should appear?)

Through steps 2.0 - 2.1 the Job WO??? would have appeared at Documents > ECB > Welding Jobs....and then been removed from the list following process 2.1

*This Raw Stock product is at a warehouse location z.

Relevant Reports

- Reports > Production > Assembly Weld

- Reports > Production > ........................

Page 3

ECB Scanning Manufacturing Flow

2. Sell Finished Product from RAW Stock Warehouse

Use a raw product to fulfill a Sales Order. This is a core activity, the customer can determine the type of finish the bar gets. That is, the bar is there waiting for the order to come through, to determine the finish. That is, the bar does not have to be made from scratch, thus reducing delivery time.

LILAC Desktop

A. Sales Order. Process: STK POL (Polished) - Example, there are other finishing options.

> Work Order.

B. Work Order.

> *Labels: Top Label + Tag with Hole - Print.

MC3300 Scanner Running LILAC Despatch Manager

3.0 New Finisher Batch - Send the bar out to apply a finish to a bar externally or internally. Finishers are warehouse locations.

- Response "New Finisher Batch 00780? Scan Destination" - > Done (Scan Finishing Location).

*New Finisher Batch -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = F Finishing. Locations at this warehouse include internal and external finishing locations.

- Response "Location FC 01? Scan Finished Bar" - > Done (Scan Barcode from Sales Work Order stipulating Polished finish).

- Response "Finished Bar 43??? Scan Raw Bar" - > Done (Scan attached Raw Barcode from Production Order).

- Response "Raw WO??? Placed in FC 01? Scan Finished Bar" END OF CYCLE ICON (should appear?).

- Next Step: Finished Return.

3.1 Finished Return - The bar comes back in from the finisher location.

- Response "Scan Return Location" - > Done (Scan a location barcode for this product to be returned to).

*Retuned Finished Bar -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = 0 F10 Warehouse.

Locations at this warehouse are 48 pages of physical locations.

- Response "Location ????? Scan Ref/Employee" - > Done (Scan employee badge)

- Response "Employee EMP?? Scan Returned Bar" - > Done (Scan finished bar)

- Response "WO??? to ????? Scan Returned Bar" END OF CYCLE ICON (should appear?)

- Next Step: Order Control

3.2 Order Control

- Response "Scan Completed Bar" - > Done (Scan finished bar)

- Response "W/O 43??? Scan Package Label" - > Done (Scan Package / Top Label)

* Package Label comes from Work Order > Labels > Top Label

- Response "Finished Product Code, Raw Product Code, ICZ???, Polish, Bal Adj, BoM Done Complete Scan Completed Bar "

END OF CYCLE ICON (should appear?)

- Combo Labels???

- Next Step: Wrapping Scan

3.3 Wrapping Scan

- Response "Scan Bar to Wrap" - > Done (Scan finished bar)

- Response "Wrapped By >>>" - > Done (Scan Employee)

- Response "Checked By >>>" - > Done (Scan Employee)

- Response "Enter Pin" - > Done (1234)

- Response "WO??? Wrapped Scan Bar to Wrap" - > END OF CYCLE ICON (should appear?)

- Next Step: Despatch

3.4 Despatch - Progresses the Work Order document to Invoice.

- Response "Scan Sales Work Order" - > Done (Scan finished bar)

- Response "Sales W/O WO??? Single Item Enter ConNote" - > Done (Scan Con Note)

- Response "Con??? Confirm Invoice" - > Done (Enter) - Progresses the Work Order document to Invoice.

- Response "Invoice Number: **??? Print it" - > Done (Enter)

- Response "" - >

Relevant Reports

Page 4

ECB Scanning Manufacturing Flow

3. Manufacture and Scan FINISHED Stock into Warehouse

Produce a finished bar from scratch for Inventory. That is, there is no current Sales order for this product. Does it get wrapped always to protect the finish? Not boxed? Should/does this product need to go over Order Control to be wrapped?

LILAC Desktop

A. Production Order. Process: Raw Stock

> Work Order

B. Work Order.

> *Labels: Tag with Hole - Print

MC3300 Scanner Running LILAC Despatch

1.0 Sign In

- Response "Type Company Id / Scan User" -> Done (Scan LILAC User Barcode.....z001).

- Response "Root Menu".

2.0 New Weld Job - Gives Welder a Work Order.

- Response "Scan Employee Badge"-> Done (Scan Employee Badge).

- Response (If no job) "No Job for EMP??" Go to: Documents > ECB > Welding Jobs: Refresh. This will release a job.

- Response. Gets assigned an available Work Order. "Welder RE??? ? on job WO??? Product Code x Quantity".

END OF CYCLE ICON (should appear?).

- At this stage he doesn't / he is not asked to scan the Raw Stock Barcode he is working on. He only does this when he finishes...which is a bit strange.....as he could well be working on the wrong bar....only to find an incompatable scan at the next step Welding Complete.

Response could request Scan Raw Stock Label: From Raw Stock Work Order.

- Next step go back in menu to find Welding Complete.

2.1 Welding Complete

- Response "Scan Employee Badge"-> Done (Scan Employee Badge)

- Response "EMP?? Active Location 3z 999 Scan Labels"-> Done (Scan Raw Stock Label: From Raw Stock Work Order)

- Response "WO??? ? to location 3z 999 Order Control:

- Work Order Complete END OF CYCLE ICON (should appear?)

Through steps 2.0 - 2.1 the Job WO??? would have appeared at Documents > ECB > Welding Jobs....and then been removed from the list following process 2.1

*This Raw Stock product is at a warehouse location z.

3.0 New Finisher Batch - Send the bar out to apply a finish to a bar externally or internally. Finishers are warehouse locations.

- Response "New Finisher Batch 00780? Scan Destination" - > Done (Scan Finishing Location).

*New Finisher Batch -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = F Finishing. Locations at this warehouse include internal and external finishing locations.

- Response "Location FC 01? Scan Finished Bar" - > Done (Scan Barcode from Sales Work Order stipulating Polished finish).

- Response "Finished Bar 43??? Scan Raw Bar" - > Done (Scan attached Raw Barcode from Production Order).

- Response "Raw WO??? Placed in FC 01? Scan Finished Bar" END OF CYCLE ICON (should appear?).

- Next Step: Finished Return.

3.1 Finished Return - The bar comes back in from the finisher location.

- Response "Scan Return Location" - > Done (Scan a location barcode for this product to be returned to).

*Retuned Finished Bar -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = 0 F10 Warehouse.

Locations at this warehouse are 48 pages of physical locations.

- Response "Location ????? Scan Ref/Employee" - > Done (Scan employee badge)

- Response "Employee EMP?? Scan Returned Bar" - > Done (Scan finished bar)

- Response "WO??? to ????? Scan Returned Bar" END OF CYCLE ICON (should appear?)

- Should this product need to go over Order Control to be wrapped?

Relevant Reports

Page 5

ECB Scanning Manufacturing Flow

4. Sell Finished Product from FINISHED (boxed or un-boxed) from Stock Warehouse

- A Sales Order picks up a finished product, despatches and invoices it. Where this bar comes from will depend if it is wrapped, boxed, or sitting finished in the warehouse. Is it wrapped to protect the finish and keep dust off?

LILAC Desktop

A. Sales Order. Process: STK Boxed???? (Polished????) - Example, there are other finishing options.

> Work Order.

B. Work Order.

> *Labels: Will already be on the bull bar in the box. So Print the Combo labels that go on the actual box.

MC3300 Scanner Running LILAC Despatch * If un-wrapped and un-boxed

3.2 Order Control

- Response "Scan Completed Bar" - > Done (Scan finished bar)

- Response "W/O 43??? Scan Package Label" - > Done (Scan Package / Top Label)

* Package Label comes from Work Order > Labels > Top Label

- Response "Finished Product Code, Raw Product Code, ICZ???, Polish, Bal Adj, BoM Done Complete Scan Completed Bar "

END OF CYCLE ICON (should appear?)

- Combo Labels???

- Next Step: Wrapping Scan

3.3 Wrapping Scan

- Response "Scan Bar to Wrap" - > Done (Scan finished bar)

- Response "Wrapped By >>>" - > Done (Scan Employee)

- Response "Checked By >>>" - > Done (Scan Employee)

- Response "Enter Pin" - > Done (1234)

- Response "WO??? Wrapped Scan Bar to Wrap" - > END OF CYCLE ICON (should appear?)

- Next Step: Despatch

3.4 Despatch - Progresses the Work Order document to Invoice.

- Response "Scan Sales Work Order" - > Done (Scan finished bar)

- Response "Sales W/O WO??? Single Item Enter ConNote" - > Done (Scan Con Note)

- Response "Con??? Confirm Invoice" - > Done (Enter) - Progresses the Work Order document to Invoice.

- Response "Invoice Number: **??? Print it" - > Done (Enter?)

- Response "" - >

MC3300 Scanner Running LILAC Despatch * If wrapped and boxed

3.4 Despatch - Progresses the Work Order document to Invoice.

- Response "Scan Sales Work Order" - > Done (Scan finished bar)

- Response "Sales W/O WO??? Single Item Enter ConNote" - > Done (Scan Con Note)

- Response "Con??? Confirm Invoice" - > Done (Enter) - Progresses the Work Order document to Invoice.

- Response "Invoice Number: **??? Print it" - > Done (Enter?)

- Response "" - >

Relevant Reports

Page 6

ECB Scanning Manufacturing Flow

5. Sell Finished Product from Sales Order

A Sales Order, from the Web or otherwise, manufactures a finished product from scratch, despatches and finishes it..

A. Sales Order. Process: POL??? (Polished) - Example, there are other finishing options.

> Work Order.

B. Work Order.

> *Labels: Top Label + Tag with Hole - Print.

1.0 Sign In

- Response "Type Company Id / Scan User" -> Done (Scan LILAC User Barcode.....z001).

- Response "Root Menu".

2.0 New Weld Job - Gives Welder a Work Order.

- Response "Scan Employee Badge"-> Done (Scan Employee Badge).

- Response (If no job) "No Job for EMP??" Go to: Documents > ECB > Welding Jobs: Refresh. This will release a job.

- Response. Gets assigned an available Work Order. "Welder RE??? ? on job WO??? Product Code x Quantity".

END OF CYCLE ICON (should appear?).

- At this stage he doesn't / he is not asked to scan the Raw Stock Barcode he is working on. He only does this when he finishes...which is a bit strange.....as he could well be working on the wrong bar....only to find an incompatable scan at the next step Welding Complete.

Response could request Scan Raw Stock Label: From Raw Stock Work Order.

- Next step go back in menu to find Welding Complete.

2.1 Welding Complete

- Response "Scan Employee Badge"-> Done (Scan Employee Badge)

- Response "EMP?? Active Location 3z 999 Scan Labels"-> Done (Scan Raw Stock Label: From Raw Stock Work Order)

- Response "WO??? ? to location 3z 999 Order Control:

- Work Order Complete END OF CYCLE ICON (should appear?)

Through steps 2.0 - 2.1 the Job WO??? would have appeared at Documents > ECB > Welding Jobs....and then been removed from the list following process 2.1

*This Raw Stock product is at a warehouse location z.

3.0 New Finisher Batch - Send the bar out to apply a finish to a bar externally or internally. Finishers are warehouse locations.

- Response "New Finisher Batch 00780? Scan Destination" - > Done (Scan Finishing Location).

*New Finisher Batch -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = F Finishing. Locations at this warehouse include internal and external finishing locations.

- Response "Location FC 01? Scan Finished Bar" - > Done (Scan Barcode from Sales Work Order stipulating Polished finish).

- Response "Finished Bar 43??? Scan Raw Bar" - > Done (Scan attached Raw Barcode from Production Order).

- Response "Raw WO??? Placed in FC 01? Scan Finished Bar" END OF CYCLE ICON (should appear?).

- Next Step: Finished Return.

3.1 Finished Return - The bar comes back in from the finisher location.

- Response "Scan Return Location" - > Done (Scan a location barcode for this product to be returned to).

*Retuned Finished Bar -> Goes to a location defined at Documents > Warehouse > Location. Warehouse ID = 0 F10 Warehouse.

Locations at this warehouse are 48 pages of physical locations.

- Response "Location ????? Scan Ref/Employee" - > Done (Scan employee badge)

- Response "Employee EMP?? Scan Returned Bar" - > Done (Scan finished bar)

- Response "WO??? to ????? Scan Returned Bar" END OF CYCLE ICON (should appear?)

3.2 Order Control

- Response "Scan Completed Bar" - > Done (Scan finished bar)

- Response "W/O 43??? Scan Package Label" - > Done (Scan Package / Top Label)

* Package Label comes from Work Order > Labels > Top Label

- Response "Finished Product Code, Raw Product Code, ICZ???, Polish, Bal Adj, BoM Done Complete Scan Completed Bar "

END OF CYCLE ICON (should appear?)

- Combo Labels???

- Next Step: Wrapping Scan

3.3 Wrapping Scan

- Response "Scan Bar to Wrap" - > Done (Scan finished bar)

- Response "Wrapped By >>>" - > Done (Scan Employee)

- Response "Checked By >>>" - > Done (Scan Employee)

- Response "Enter Pin" - > Done (1234)

- Response "WO??? Wrapped Scan Bar to Wrap" - > END OF CYCLE ICON (should appear?)

- Next Step: Despatch

3.4 Despatch - Progresses the Work Order document to Invoice.

- Response "Scan Sales Work Order" - > Done (Scan finished bar)

- Response "Sales W/O WO??? Single Item Enter ConNote" - > Done (Scan Con Note)

- Response "Con??? Confirm Invoice" - > Done (Enter) - Progresses the Work Order document to Invoice.

- Response "Invoice Number: **??? Print it" - > Done (Enter)

- Response "" - >

Page 2

ECB Scanning Manufacturing Flow

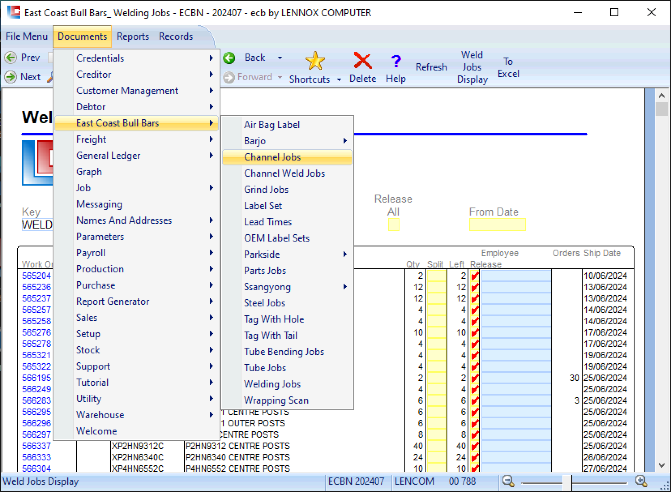

6. Documents - Jobs - Displays

Within the LILAC menu, Documents > East Coast Bull Bars there are a number of documents which are in fact tables / lists of jobs to be allocated and completed on the factory floor. These tables / lists can be displayed on a large black screen on the factory floor and updated / refreshed every minute as the jobs are progressed by the employee via scanning.

Quick Break Down of Jobs / Tables - 20240708

- Channel Jobs:

- Channel Weld Jobs:

- Grind Jobs: rr

- Parts Jobs:

- Steel Jobs:

- Tube Bending Jobs:

- Tube Jobs:

- Welding Jobs: